Click here to go back to Lukes Racing Big Bore Kits

Click here to go back to Lukes Racing 4 Stroke Labor Page

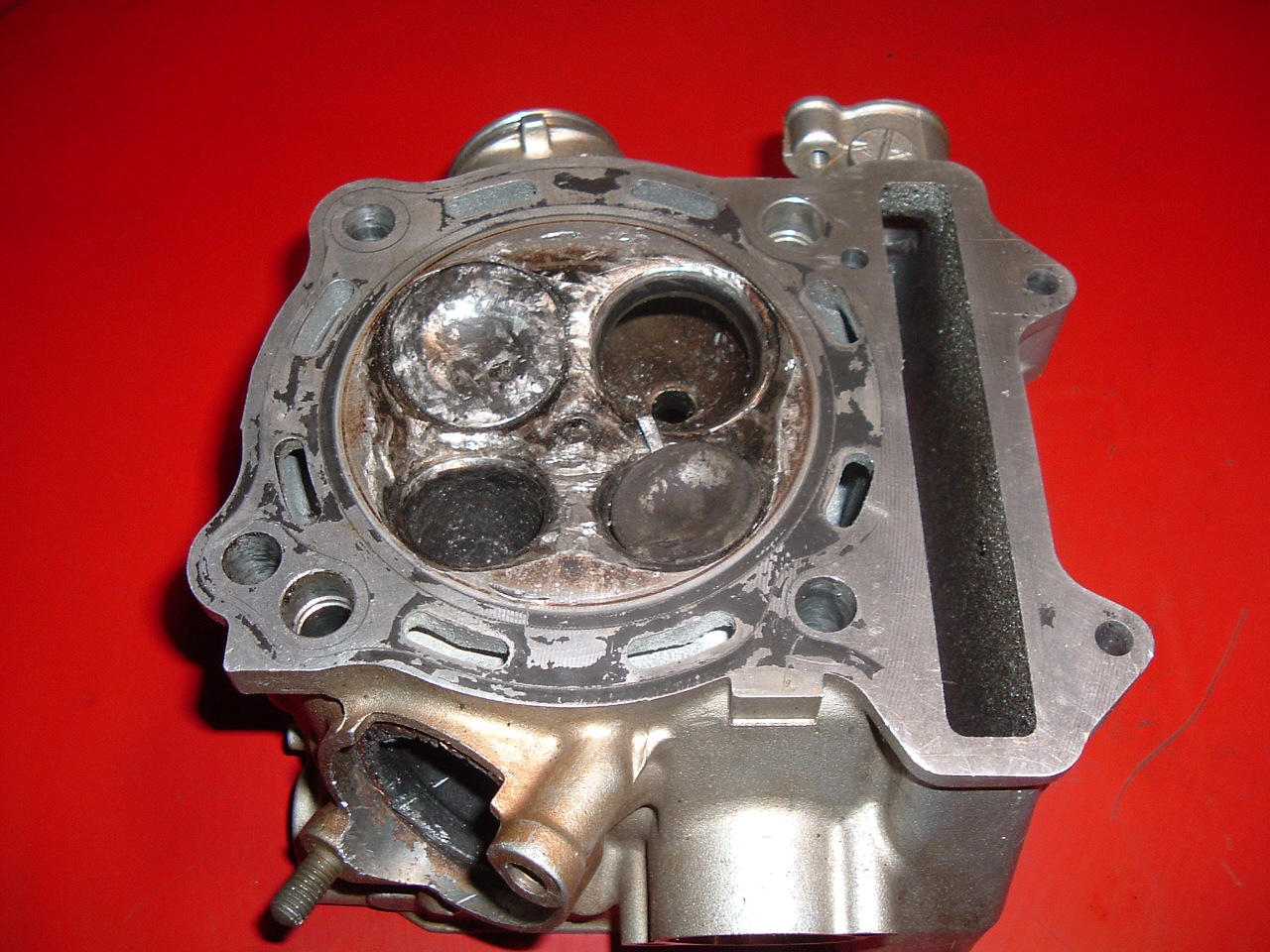

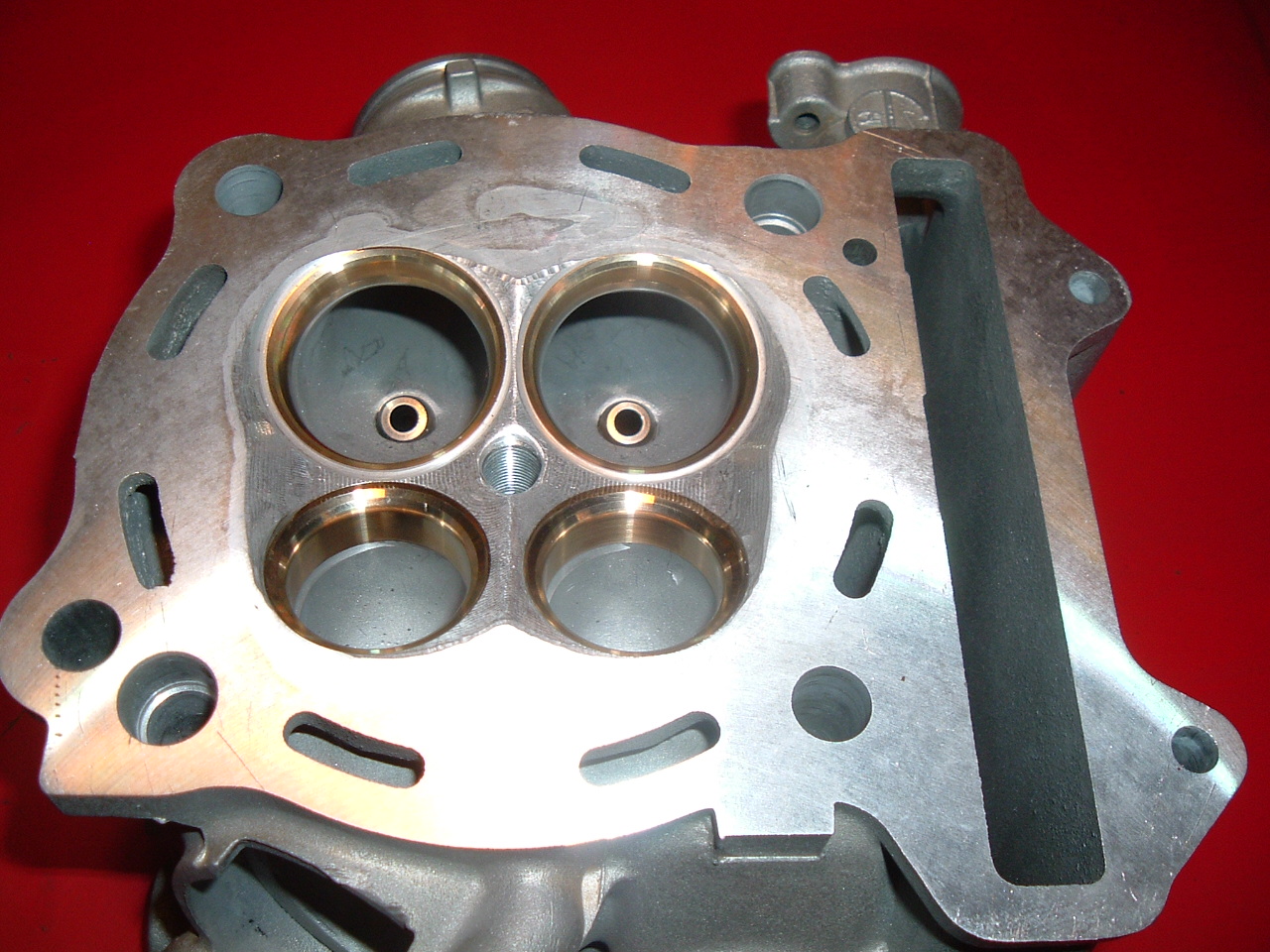

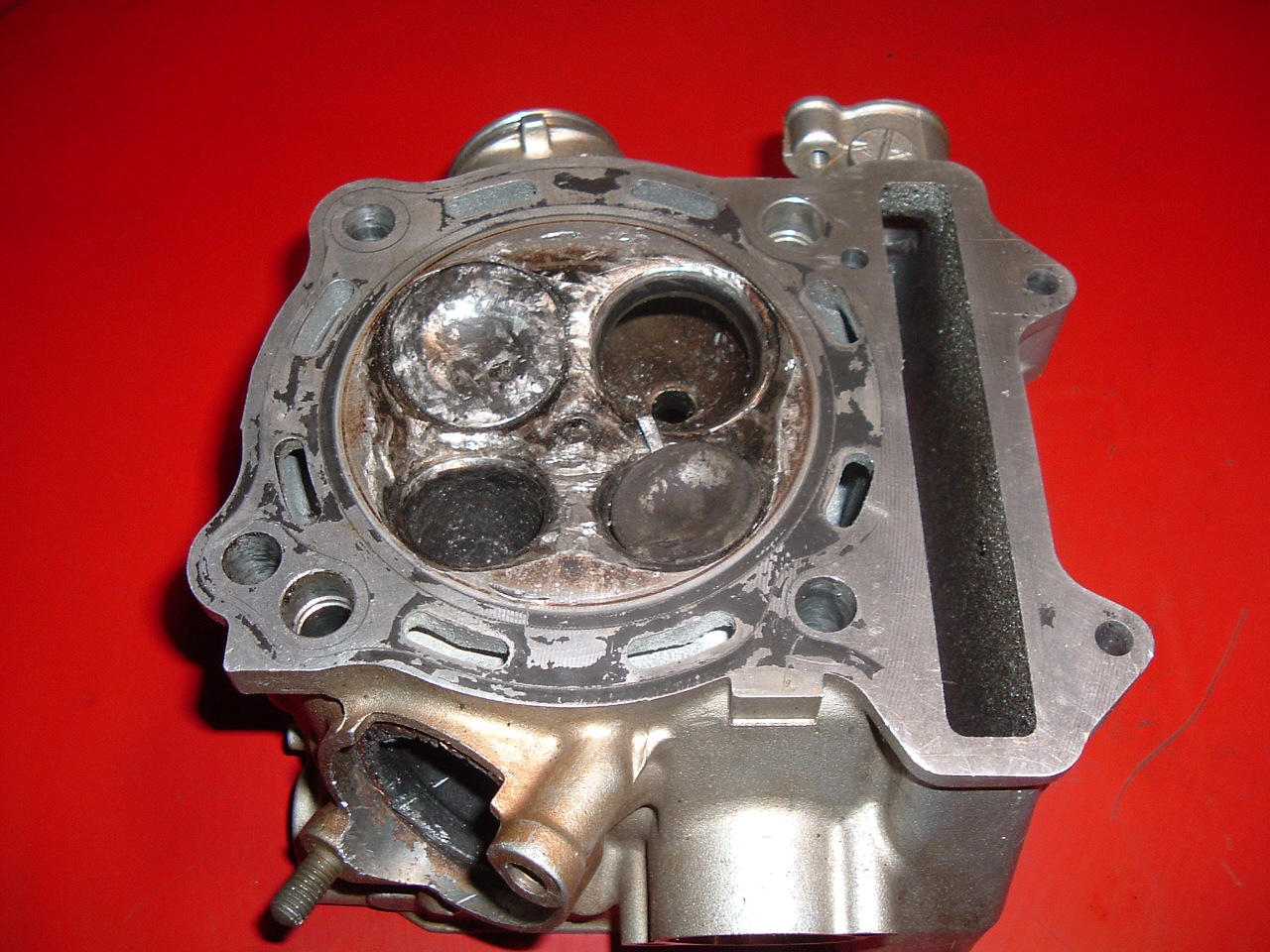

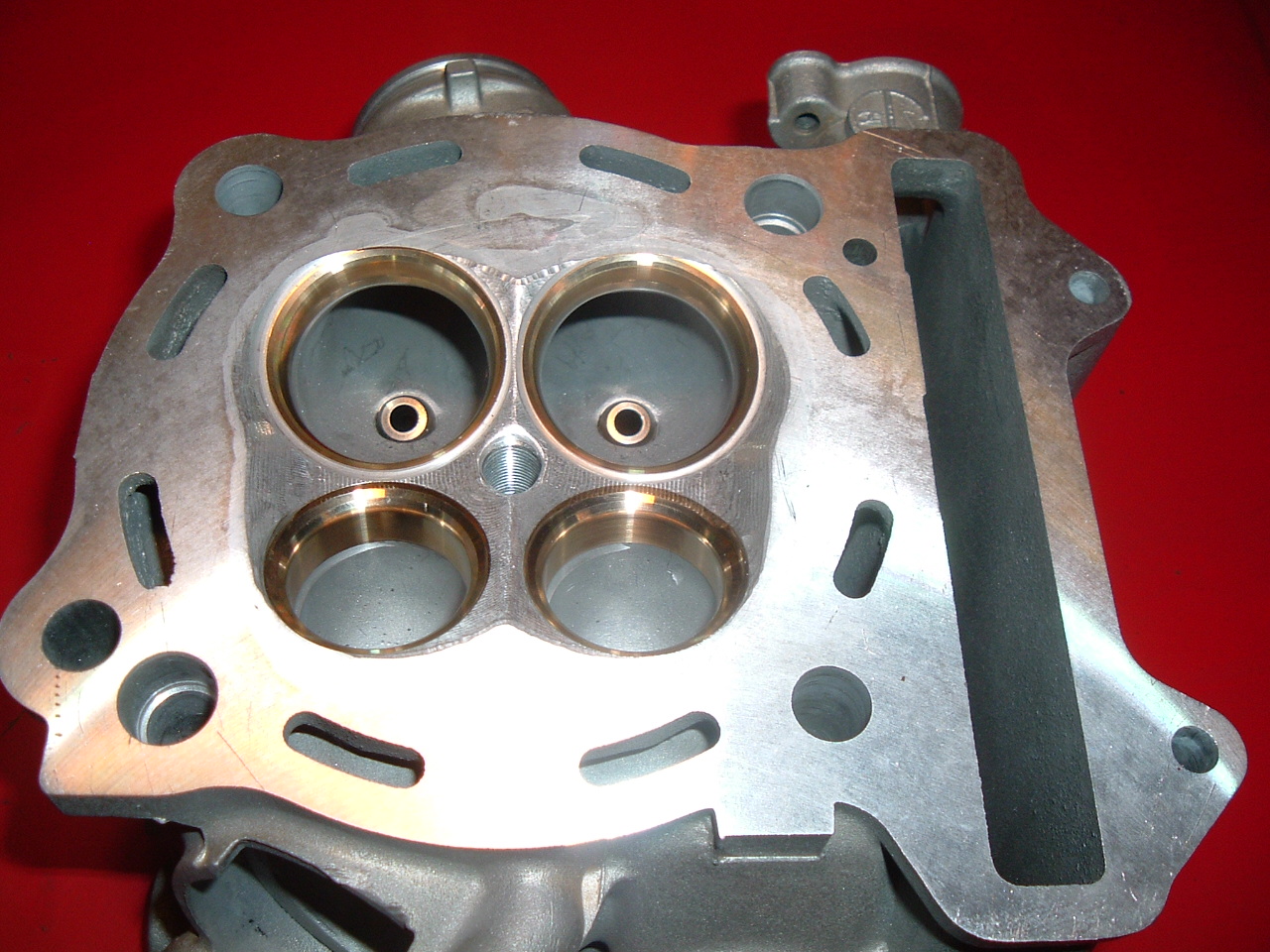

4-Stroke Head repair

Before and after pictures of our rebuild heads. See links below for more info

Click here to go back to Lukes Racing Home page

Click

here to go back to Lukes Racing Big Bore Kits

Click here to go back to Lukes Racing 4 Stroke

Labor Page

4-Stroke Head repair

Before and after pictures of our rebuild heads. See links

below for more info

1. Valve guides and seats are removed.

2. Heads are TIG welded.

3. Valve guides and seats are replaced with AMPCO® 45 (a high strength nickel-aluminium

bronze alloy). AMPCO® 45 transfers heat better than factory valve seats,

Has better wear qualities and reduces wear on the valve face, Is compatible

with Stainless steel and titanium valves.

4. Combustion chamber is CNC machined back to factory dimensions using a Centroid

CNC head porting machine. Spark plug hole is re-threaded

5. Valve seats are re-machined using a Newen CNC valve seat cutting machine.

Click here to see a video of the Centroid CNC head porting

machine

Click

here to read about the Centroid CNC head porting machine

here is a quote from www.stockcarracing.com "Until

just a few years ago, the Serdi was often seen as the state-of-the-art machine

and was most used by the top pro racing shops. These days, there is a new player

on the block when it comes to generating high-tech seat designs-the single-point-tool

CNC Newen machine"

Click

here to read the article about the Newen CNC valve seat cutting machine on stockcarracing.com